INTERVIEW

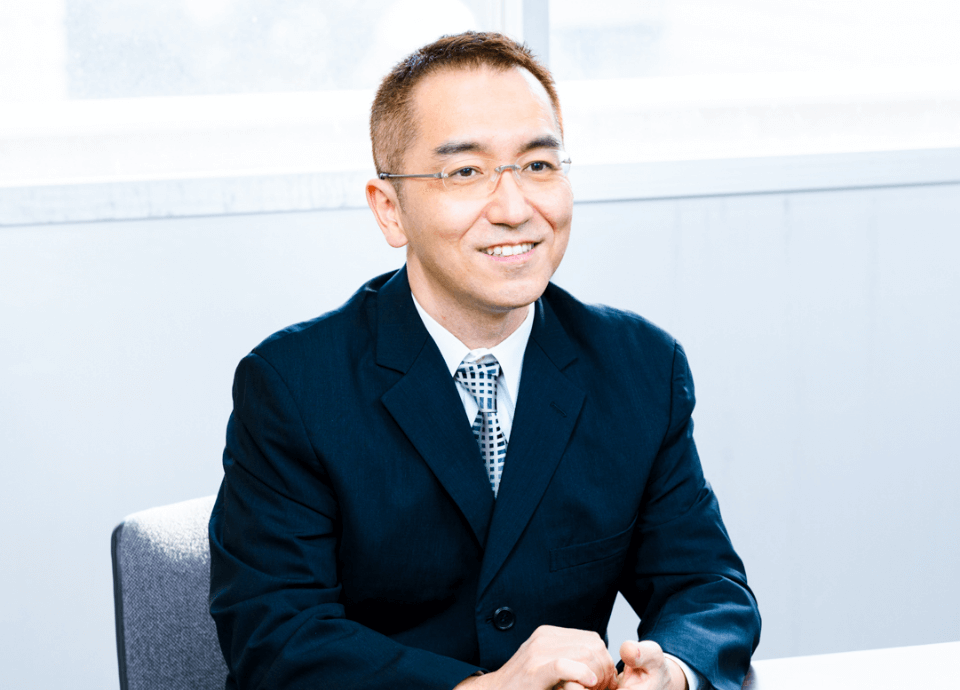

KENTA YAMAGIWA National Institute of Occupational Safety and Health

PROFILE

Mainly active in fracture surface analysis and accident investigation, as well as related lectures and academic activities. He has been involved in fracture surface analysis research since he was a graduate student. After graduation, he worked at the National Institute of Occupational Safety and Health.

Kenta YAMAGIWA

| Hometown: | Shimizu City, Shizuoka Prefecture (now Shimizu-ku, Shizuoka City), Japan |

| Affiliation: |

|

| Membership: |

|

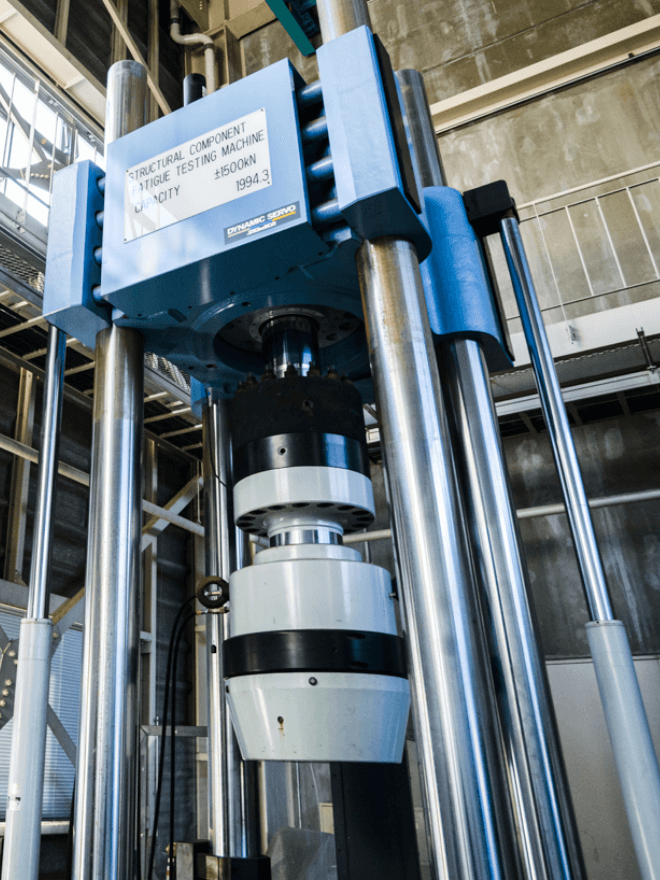

| Job Description: | Investigation and appraisal commission of industrial accidents |

| Main Research: | Fracture surface analysis and material strength |

| June 2003: | Completed coursework for Doctoral Program in Mechanical Engineering, Graduate School of Engineering, University of Tokyo |

| July 2003: | Employed at National Institute of Industrial Safety (currently known as National Institute of Occupational Safety and Health) |

| March 2004: | Awarded doctoral degree in Engineering for research on "Characterization of fracture surfaces by introducing local parameters" |

| September 2007 to February 2008: | Visiting Scholar:Department of Mechanical Engineering, University of Utah |

| April 2013: | Concurrently appointed as Visiting Professor (summer semester, equipment safety engineering) at Tokyo Denki University (Graduate School) |

| 2005-2007: | Health and Labor Sciences Research Grants (Quantitative Analysis System Development for Estimating Fracture Load from Fracture Surface) |

| 2009-2011: | Grants-in-Aid for Scientific Research (B) "Measurement of 3D Geometry of Creep Voids and New Life Evaluation Method Based on Void Volume Fraction" KAKEN |

| 2013: | Research Grant from Japan Boiler Association "Three-Dimensional Quantitative Evaluation of External Pipe Corrosion and Corrosion Simulation Material Based on Fractal Concept" |

Japan Society for Material Science Paper Award (2002)

ALL Interviewed by

| Produce | TARO MATSUMOTO (GiRAFFE & Co.) |

| Photo | KOKI MATSUNAGA |

| Hair Make | YUKA KURIHARA |

| Direction | YUMI SHIMOTAHIRA (GiRAFFE & Co.) |

| Writing | YUKI KAWATO (GiRAFFE & Co.) HARUNA MIKAMI (GiRAFFE & Co.) |

| Design | YUKI KAWATO (GiRAFFE & Co.) HARUNA MIKAMI (GiRAFFE & Co.) |